In today’s business environment, more than ever before, the only constant is change. Given current uncertainties and dynamic market conditions, the pressure on management to plan for the future gets highly difficult – at some point, impossible. Drawing up scenarios for potential situations is difficult at best, and looking back over the last three years – the number of companies successfully pinpointing current situations is slim to none. From now on, are we expecting to see more stable conditions and things returning to normal? Perhaps, but what would be the new normal? More importantly – How does one plan for the unexpected, and how to do so in a simple way?

Over the last few years, the rate and magnitude of changes in the market have been increasing dramatically and, therefore, becoming more unpredictable. Material availability, supply chain and logistical difficulties, increased interest rates with financing challenges, and soaring energy and raw material prices are examples of challenges in the market. Still, these are aspects of the business climate that companies must manage to succeed or, in some cases, stay in business. Add to that, disruptive business models could completely reshape the market. Challenging? Yes, but this also presents a wide range of opportunities for companies that are well-prepared and can quickly manage to adapt. This insight will provide you with an approach and a starting point.

Getting started

When planning for the future, applying traditional scenarios and business modeling would – given the situation described earlier – result in, for lack of a better word – a long list of potential scenarios and equally many action plans. Is it even possible or justifiable to invest such a significant amount of time and resources in continuously staying ahead and making sure all angles are covered, or might there be another

approach? Maybe a different approach, or at least applying a different lens, to strategic scenario planning is necessary that does not focus too much on what may happen but rather focus on what changes to key business parameter values the business needs to account for. Gearing the business to be able to adapt quickly and respond to new situations is critical to stay ahead in the game or even being able to survive. Rapid up- or down-scaling, managing market exits or new market entries, etc. are typical examples of situations that would be part of that critical list. For those that prepare well and in the right way – opportunities will most definitely present themselves. So, where do you start? It is easy to get overwhelmed by the number of different business drivers, market parameters, supply chain aspects, global perspectives, and so on.

Well, get back to basics. Make sure you know your business and current position.

Know your home turf!

Before even stretching the mind in diving into scenario development initiatives, the initial action is to define your playground. That is – in what space do we operate and how? It includes drawing up boundaries regarding markets and geographies, customers, product(s) (area)s, supplier base, and business processes. Agreeing on this might seem basic, yet fundamentally important going forward. A current state assessment, complementing the business landscape definition, can be achieved by adding Key Performance Indicators.

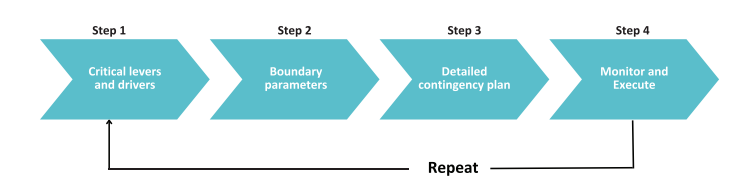

Figure 1: Step-by-step approach to generate a plan for the unexpected

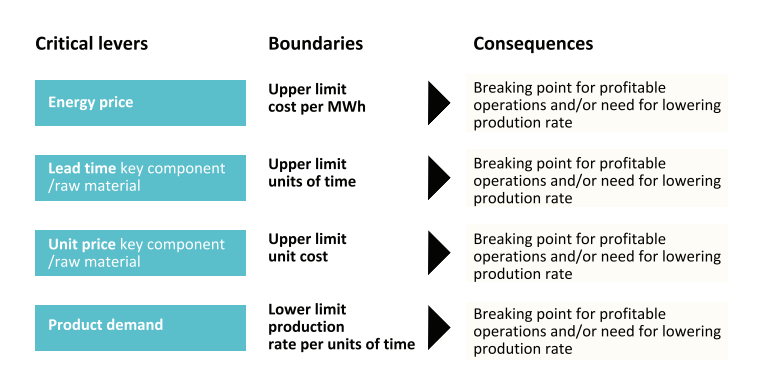

Figure 2: Drivers impacting the business situation (examples)

The step-by-step approach Companies should adopt a proactive rather than a reactive approach and attempt to influence, predict, and initiate rather than just respond to events. There are many ways and techniques in working with scenario planning which sometimes goes above and beyond simple and quick. Nothing wrong with this, but a simple and useable approach would be favorable. As such – keeping this simple is key!

Step 1 – Critical levers and drivers

Identify, understand, and prioritize the business drivers that truly impact and create maximum value for the business. Various factors and trends are coming from inside and outside the organization that can be considered pressures or opportunities for identifying these critical drivers. Therefore the list can initially be quite exhaustive and comprehensive. Everything tends to be important, right? The challenge is rarely not to come up with a list, and the trick is to narrow it down to what truly matters. Remember, your business always manages to change market conditions – this exercise should not aim to support daily operations and generate oversight. It is about planning for the unexpected and providing the best possible prerequisites to act when needed and minimize the impact.

Step 2 – Boundary parameters

When finalizing the list of critical drivers, there is an opportunity to specify what signals to look for. For each of the ones listed in the previous step, the “upper and lower limit”- approach (depending on type of driver) can be used to set boundaries. The Lower or Upper limit aspect could be applied to several different areas such as resource availability, resource lead times, resource price points, sales volumes, sales price, production volume, and so on. For instance, the upper limit price point on a specific key raw material to maintain product break-even, or the lower limit production volume to ratify keeping operations running. Furthermore, the examples above could easily be considered manufacturing oriented but are equally related to the service industry, B2C as well as B2B.

Step 3 – Detail contingency plan

The objective is to keep the list of critical drivers (in step 1) relatively short by focusing on the most critical ones. The number of different action plans could then be kept at a manageable level, and this is where an alternative approach to scenario planning could make a difference. Emphasizing the fact that a contingency plan, in this case, should be a proper contingency case and something that has not happened yet.

Figure 3: Critical levers and boundary parameters to look for in a Manufacturing company (examples)

Also, a true contingency would not be something that would/could be managed within ordinary operations or seen as a general management assignment. It needs to be something truly out of the ordinary. For instance, supply contingency actions, preparations for rapid operations down-scaling, and quickly exiting a specific market are all examples of preventive and defensive actions. In addition, there might also be actions that relate to capturing extraordinary market opportunities such as acquisitions, competitive pricing opportunities or other market expansion initiatives.

Also, a future scenario may end with a need to execute more than one action plan. In that case, there is a strong need to manage potential interdependencies across several plans. A contingency plan should also include a communication strategy to ensure that everyone involved is kept informed. The level of detail may vary but should be kept at a reasonable level and focus on the key deliverable(s) within the specific

plan. A contingency or action plan should include relevant guidance on “What to do”, “When to do it” and “By whom”

Step 4 – Monitor and execute

Executing a contingency plan could be a chapter in itself. Sharp executive decision-making, clear communication, and robust action are key elements in achieving results, and several aspects could be discussed and debated. This could be the topic for a separate piece. So, with that in mind, this section is dedicated to planning. Once the plan(s) are set and detailed, the monitoring phase is important to not only identify signals that may trigger the execution of an action plan but also to look for signs that may prompt a review of previous steps. The status quo in the market is something rarely seen, and selected intervals recommend a continuous review. Boundary parameters may be reviewed, or contingency plans may no longer be relevant or possible to execute. The monitoring phase also requires an understanding of what parameters to follow. For a specific raw material or product, it could be monitoring specific raw-material price development, indices, etc., or the cost of

shipping or perhaps restrictions affecting the use of components, additives, or similar that ultimately affect the availability, price or lead time of that key raw material critical for your business.

Figure 4: Plans and alternative plans can be executed separately, in parallel or in part as they may impact one or the other

Summary

The approach described in this insight is not meant to put scenario planning on the sideline. Several benefits and proven techniques are very good at supporting strategic discussions and are well worth keeping. Also, it has been proven! This document aims to highlight the possibilities of looking at scenario planning from another perspective. The complexity of the process itself may be reduced. However, the need for strategic review and analysis of the key drivers and levers affecting your business operations remains. As the business environment changes, it will probably become even more complex. As such, focusing on what truly matters and making the most of simplifying the approach when possible is still valid and could ease the burden of management across various industries.

Key takeaways

The approach to Scenario planning can be simplified

Having a plan is half the battle, but don’t plan for everything – only focus on what is important

Most scenarios must be part of (daily) operations – the ones that do not qualify for that are the ones that truly need a contingency plan on the management level